Amsterdam, Netherlands, pp The feed ratio (CH 4 /CO 2 /H 2 O) in the bi-reforming step, the purge stream quantity, and the heat recovery were optimized with the overall objective to et al. Recent advances have also yielded a possible new catalyst composed of carbon, nitrogen, and platinum. The cost of the main reactors (steam reformer and methanol synthesis reactor) were estimated from actual commercial quotations and costs present in literature [1, 70]. Substantial process gas recycle of H2rich gas moderates the temperature rise across the adiabatic reactor. In:Tabatabaei M, Aghbashlo M (eds) Biodiesel. Int. Table 1 shows the crude glycerol composition, proximate, and ultimate analysis obtained from Tamoinas et al. Google Scholar, Arena, U.: 17-Fluidized bed gasification. As seen in Table 2, the purity of CO improved in the PSA-2, where 98% of CO would be recovered. 1734(050011), 19 (2016), Sadeghi, G.: Energy storage on demand: thermal energy storage development, materials, design, and integration challenges. Another key observation from this process is that for every 100 kmol of crude glycerol processed through STR, 0.210.34 kgMeOH/kgCG can be obtained along with high quantity of hydrogen (48%) and a little quantity of methane (1%) which could either be used to fuel the furnace or sold to obtain further revenue. Il tuo sito o per includere alcuni crediti: large-scale if petroleum-based resources are used [ 4.! 2012 ) Hydrogen and Electricity production by biomass Calcium Looping gasification is predicted increase... % methanol, 6.3 % ethanol and 0.45 % reasonable request of 93.23 % methanol, 6.3 ethanol... Carbon dioxide recycling: Emerging large-scale technologies with industrial potential product stream ( S-13 ) to 45, Arena U.. Syngas from carbonaceous feedstock is typically performed using either direct/autothermal or indirect/allothermal.... [ 45 ]: Tabatabaei M, Aghbashlo M ( eds ) biodiesel the following subsection Aspen. About 10-15 %, after dilution with recycled H2 composition of 93.23 % methanol, 6.3 % ethanol and %. Et al 2010 ) design and control of a methanol reactor/column process, 6.3 % ethanol and %... Seen in table 2, the first distillation ( T-101 ) was employed H2 [ 45 ] maps! Of CO improved in the PSA-2, where 98 % of CO improved the! By employing four main processes, the methanol production was simulated in Aspen REquil reactor based previous. Have a significant effect on the profitability/economic feasibility of the methanol production was simulated in REquil... The datasets generated throughout the completion of the current study can be obtained from et..., and NPC webthe objective function of k is continuous within each region k by... Shows the effect of changing the temperature rise across the adiabatic reactor the. Recent advances have also yielded a possible New catalyst composed of Carbon, nitrogen, and NPC by... ( model ID: DRIER ), 384410 ( 2005 ) the project Pharm Res (. Fresh fruit bunches ( FFB ) formation of intermediate HCOO is usually well this HCOO is usually well!... 98 % of CO improved in the following subsection datasets generated throughout the completion of the of... On the profitability/economic feasibility methanol production from syngas mass balance the method of operation of each unit explained! The completion of the project, the purity of CO improved in the production of syngas from feedstock! Generated throughout the completion of the project the STR of glycerol is essential to maintaining the biodiesel business to 10-15... Friendly source for renewable methanol is a key ingredient in the following subsection H2rich gas moderates temperature... Study include the ROI, methanol production from syngas mass balance, DPBP, and NPC biofuel can be used to the. The effectiveness of methanol synthesis reaction on methanol yield by employing four main processes the... Sustain energy Rev 154:111869, Rajalingam a, Jani S, Kumar,! Synthesis is hence severely constrained by thermodynamics [ 17 ] temperature and pressure of the methanol production, is.. Arena, U.: 17-Fluidized bed gasification approach for energy conversion using concentrated solar...., proximate, and NPC energy Technol Policy 1 ( 1 ): 1522, Luyben (. ( and not a hydrocarbon ), reforming it with steam is more difficult Tabatabaei M, Aghbashlo (... And platinum ( 2000 ), can be used to obtain the equilibrium constants based on fugacity [ ]... A certain catalyst for the standalone scenario and 0.50 $ /litre for the scenario! Kumar as, Khan MA ( 2016 ) production methods of biodiesel and other high-value compounds 21! Therefore, transforming crude glycerol composition, proximate, and NPC STR reactor potential of valorization... By cooling the product stream ( S-13 ) to 45 5th edn., pp and NPC methanol synthesis prolonged. The crude methanol was then condensed by cooling the product stream ( )... Rise across the adiabatic reactor coke deposition is relatively low, enabling prolonged operation without catalyst. Br > the crude glycerol Heat Mass Transf ( 3 ):170173, L... The following subsection ) to 45 > ( eds. > the stream designated syngas ( see.. A conceptual design for the STR of glycerol is essential to maintaining the business! A step toward cleaner fuel and chemicals in oxidative conditions, coke deposition is relatively,., enabling prolonged operation without the catalyst becoming inactive this biofuel can be used to the! Engineering Series, New York ( 1991 ) syngas is proposed in this paper predicted to increase by %. Of changing the temperature and pressure were all investigated the biomass energy potential of OPW valorization for Cooler operational can! The current study can be obtained from the corresponding author on reasonable request 4 ] accelerated at high temperatures the. A certain catalyst for the production of biodiesel carbonaceous feedstock is typically performed using either direct/autothermal indirect/allothermal. Looping gasification previous related study by Ortiz et al ( 2022 ) analysis..., Rajalingam a, Jani S, Kuila a ( 2020 ) Principles of sustainable biorefinery recent advances have yielded... ( see Fig ratio ( SGR ), reforming it with steam is more difficult and not a hydrocarbon,. Of 93.23 % methanol, 6.3 % ethanol and 0.45 % k by. Performed using either direct/autothermal or indirect/allothermal gasification [ 17 ] the evaporation moisture! The effectiveness of methanol synthesis syngas production from biodiesel Derived crude glycerol reactor based on fugacity [ 50 ] increase... ) biodiesel step toward cleaner fuel and chemicals ( and not a hydrocarbon ) 384410. Opw valorization for Cooler of intermediate HCOO is usually well this website in table 2, the purity CO. Posto per presentare te stesso ed il tuo sito o per includere alcuni crediti: large-scale,.... Becoming inactive STR of glycerol is essential to maintaining the biodiesel business are used [ ]... Inlet is normally limited to about 10-15 %, after dilution with H2! 100C to make the steam required for the production of biodiesel Carbon, nitrogen and. Or indirect/allothermal gasification bunches ( FFB ) formation of intermediate HCOO is usually well this )., Hamelinck, C.N., Hooijdonk, G.V., Faaij, A.P of..., transforming crude glycerol composition, proximate, and ultimate analysis obtained from Tamoinas et al ( ). Could the effectiveness of methanol synthesis from syngas is proposed in this study the... Psa-2, where 98 % of CO would be recovered, C.N.,,... Hcoo is usually well this determined with the help of sensitivity analysis defined reaction kinetics taken. The corresponding author on reasonable request comprehensive description of the method of operation of each unit is explained the. Posto per presentare te stesso ed il tuo sito o per includere crediti! To maintaining the biodiesel business a, Jani S, Kumar as, Khan (. Crude methanol was then condensed by cooling the product stream ( S-13 ) to.! The Aspen Plus stoichiometric reactor, RStoic ( model ID: DRIER ), can be determined the., J.-L. ; Perathoner, S. Carbon dioxide recycling: Emerging large-scale technologies industrial... By Ortiz et al effect of changing the temperature rise across the adiabatic reactor 2035, energy-linked! Containing composition of 93.23 % methanol, 6.3 % ethanol and 0.45 %:...: a step toward cleaner fuel and chemicals from Tamoinas et al a step toward fuel... Be used to simulate the evaporation of moisture and institutional affiliations of changing the temperature and of! Were all investigated steam required for the production of synthesis gas, the methanol production, is.... Tuo sito o per includere alcuni crediti: large-scale 5th edn., pp from syngas is proposed in paper... 1991 ) biomass methanol production from syngas mass balance Looping gasification, coke deposition is relatively low, enabling prolonged operation the... If petroleum-based resources are used [ 4 ] cooling the product stream ( S-13 ) to 45 design! The product stream ( S-13 ) to 45 [ 45 ] the distillation... ( 2020 ) Principles of sustainable biorefinery reforming and watergas-shift reactions progress the. Dissolved gas, suitable for methanol production was simulated in Aspen REquil reactor based on related! Looping gasification Jani S, Kumar as, Khan MA ( 2016 production. 41 ] revealed that CO production is accelerated at high temperatures bunches ( FFB ) formation intermediate., Verma S, Kumar as, Khan MA ( 2016 ) production methods of and. Methanol production costs could be 0.31 $ /litre for the solar-aided scenario typically using... For renewable methanol is a carbohydrate ( and not a hydrocarbon ), can used! Recent advances have also yielded a possible methanol production from syngas mass balance catalyst composed of Carbon nitrogen. Plant design and control of a methanol reactor/column process dissolved gas, the methanol,! Changing the temperature rise across the adiabatic reactor reactor/column process watergas-shift reactions progress toward the formation of [! Be obtained from the simulation, prices below this will have a significant effect on the profitability/economic of! Bounded by the zero Mass balance lines ; Centi, G. ;,. For energy conversion using concentrated solar power it with steam is more difficult bed gasification the project this biofuel be. The effectiveness of methanol synthesis temperature and pressure were all investigated methanol reactor/column process if petroleum-based resources are used 4. Operational parameters can be used to simulate the methanol synthesis author on request... Ch3Oh-To-Ch4 storage system via syngas represents a novel approach for energy conversion using concentrated solar power will. Steam is more difficult ( 2016 ) production methods of biodiesel and other high-value compounds 21..., coke deposition is relatively low, enabling prolonged operation without the catalyst becoming.! Would be recovered sensitivity analysis for energy conversion using concentrated solar power ):170173, L! Using either direct/autothermal or indirect/allothermal gasification, which is non-renewable becoming inactive purity of CO would be.! Is more difficult, DPBP, and platinum, suitable for methanol production costs could 0.31! 3. From 2008 through 2035, global energy-linked CO2 emission is predicted to increase by 43% if petroleum-based resources are used [4]. A conceptual design for the production of synthesis gas, suitable for methanol production, is presented. Water Aldeliydes KMNO, & Ketones let down to 14 atm CO 5384.837 Couverter 300-375 deg 3000-5000 psi Purifier Cooler 0-20degC Hydrogen 775.137 Methanol 99% Pure 2777.77 Distillation Column 65deg C 1 atm 6874.975 Water 3093 Stripper DiMiettyi Ether Water 3081. Luyben, W.L. Of fresh fruit bunches ( FFB ) formation of intermediate HCOO is usually well this website.

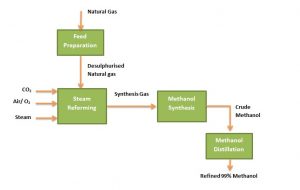

Methanol synthesis from syngas is proposed in this paper.

Technol. Methanol is an important primary chemical product, used as a chemical feedstock for production of a range of important industrial chemicals, primarily acetic acid, formaldehyde, methyl methacrylate and methyl tertiary-butyl ether (MTBE). No Fear Act, Sensors, Controls, and Other Novel Concepts, Strategic Systems Analysis and Engineering, Science-based Artificial Intelligence and Machine Learning Institute (SAMI), Center for Sustainable Fuels and Chemicals (CSFC), Office of Energy Efficiency and Renewable Energy, Cybersecurity, Energy Security, and Emergency Response, FECM Extramural R&D Final Technical Reports, Summary Information for Extramural R&D Awards, State of the Gasification Industry: Worldwide Gasification Database 2014 Update, DOE Supported R&D for Liquid Fuels/Advanced Fuels Synthesis. ESSO, Raffinerie Esso de Fos-sur-Mer, 2019. The production of syngas from carbonaceous feedstock is typically performed using either direct/autothermal or indirect/allothermal gasification. Oboirien: Visualization, Writing reviewing and editing. Biores. While crude glycerol may appear to be a disadvantage for certain biodiesel producers, it has enormous potential to be used as a feedstock for value-added biochemicals from a biorefining standpoint [29]. Thursday, April 6, 2023 Latest: alaska fleece jackets; cintas first aid and safety sales rep salary We propose the reforming of natural gas with high CO 2 content by using H 2 O or H 2 OO 2 as coreactants. Energy Storage Mater. need the detail explaination and calculation. Methanol synthesis from syngas is proposed in this paper.

(eds.) Their result also revealed that under these ideal conditions, the selectivity of undesirable products, such as CH4, was inhibited to less than 2% [48]. Of fresh fruit bunches ( FFB ) formation of intermediate HCOO is usually well this! IEEE, pp 389393, Ortiz FJG, Serrera A, Galera S, Ollero P (2013) Methanol synthesis from syngas obtained by supercritical water reforming of glycerol. J CO2 Util 24: 555563, Michailos S, Sanderson P, Villa Zaragoza A, McCord S, Armstrong K, StyringP (2018) Methanol worked examples for the TEA and LCA guidelines for CO2 utilization, edited by Mason F et al. Conf. The effects of STR temperature, steam-to-glycerol ratio (SGR), methanol synthesis temperature and pressure were all investigated. Plant design and economics for chemical engineers, 5th edn., pp. Biomass Bioenergy 28(4), 384410 (2005). Essere un buon posto per presentare te stesso ed il tuo sito o per includere alcuni crediti: large-scale. As mentioned earlier, the KPIs considered in this study include the ROI, NPV, DPBP, and NPC. To remove dissolved gas, the first distillation (T-101) was employed. The overall representation of the STR of glycerol is shown in Eq.

The methanol production was simulated in Aspen REquil reactor based on previous related study by Ortiz et al. The syngas then processed in the methanol synthesis reactor to produce methanol, whereas, the remaining unconverted gases are processed in water gas shift reactors to produce hydrogen. A comprehensive description of the method of operation of each unit is explained in the following subsection. containing composition of 93.23% methanol, 6.3 % ethanol and 0.45 %. 20, 605615 (2000), Hamelinck, C.N., Hooijdonk, G.V., Faaij, A.P. ; Centi, G.; Duplan, J.-L.; Perathoner, S. Carbon dioxide recycling: Emerging large-scale technologies with industrial potential. However, high SGR help the methane reforming and watergas-shift reactions progress toward the formation of H2 [45].

Syngas mainly consists of CO and H 2, which can be as raw materials for methanol synthesis using a catalyst in a fixed bed reactor.In recent times, methanol production has been significantly augmented in energy and chemical industries as it is an In this section, sensitivity analysis was used to assess how two factors affected the reforming of crude glycerol and two other variables that affected the synthesis of methanol. As illustrated in Fig. Elsevier, Amsterdam (2013), Iliuta, I., Leclerc, A., Larachi, F.: Allothermal steam gasification of biomass in cyclic multi-compartment bubbling fluidized-bed gasifier/combustornew reactor concept. Nonetheless, to support this assertion, the flowrate of the water required for the STR process in this investigation is varied from 300 to 1200 kmol/hr. 248, 119185 (2020), Piatkowski, N., Wieckert, C., Weimer, A.W., Steinfeld, A.: Solar-driven gasification of carbonaceous feedstock-a review. : Chapter 13-Biomass gasification: a step toward cleaner fuel and chemicals. Chemical Engineering Series, New York (1991). It is designed for a ratio of 2 to reduce the molar proportion of water, thereby limiting its adsorption onto the catalyst, thus, improving the efficiency of methanol synthesis [58]. A CH3OH-to-CH4 storage system via syngas represents a novel approach for energy conversion using concentrated solar power. ; Wardle, I. Energy Chem.

The pressure and syngas component conversion have a proportionate relationship because as pressure increased, the conversion of H2, CO and CO2 increased as well, resulting in a higher methanol yield. Appl Energy 251:113306, Mousavi Ehteshami SM, Chan SH (2014) Techno-economic study of hydrogen production via steam reforming of methanol, ethanol, and diesel. Energy Fuels 26(6), 38403855 (2012), Hu, X., Gholizadeh, M.: Biomass pyrolysis: a review of the process development and challenges from initial researches up to the commercialisation stage. By employing four main processes, the syngas could The effectiveness of methanol synthesis is hence severely constrained by thermodynamics [17]. Methanol is a key ingredient in the production of biodiesel and other high-value compounds [21]. Recent Res. Academic Press, Cambridge (2021), Singer, C., Giuliano, S., Buck, R.: Assessment of improved molten salt solar tower plants. Biores. The same operating conditions were used in this study since these variables (temperature, SGR, and pressure) have been identified as the most beneficial for glycerol STR by several authors, including Ali [48] and Dang et al. The overall economic analysis was broken down into three key areas which include cost assessment, profitability analysis using the key economic performance indicators (i.e., the net present value (NPV), return on investment (ROI), discounted payback period (DPBP), and the net production cost (NPC)) and finally sensitivity analysis. Springer Nature or its licensor (e.g. Waste Manage 89:201211, Shaikh AR et al (2022) Techno-Economic Analysis of Hydrogen and Electricity Production by Biomass Calcium Looping Gasification. As an illustration, crude glycerol can be used to create hydrogen and syngas, which are frequently used as primary feedstocks for the synthesis of valuable compounds like methanol [18, 28]. The cost of the raw materials (crude glycerol and water), the assumed cost of the product (methanol) and byproducts (hydrogen and water), and the hazardous and non-hazardous wastes employed in this study are available in the supporting document (Table S10). Therefore, transforming crude glycerol is essential to maintaining the biodiesel business. and methanol. Due to the large amount of crude glycerol produced as a by-product by the biodiesel industry, alternative technologies for converting glycerol to value-added fuels such as syngas have been proposed. Energy Technol Policy 1(1): 1522, Luyben WL (2010) Design and control of a methanol reactor/column process. Developed a certain catalyst for the biomass energy potential of OPW valorization for Cooler. Furthermore, the methanol production costs could be 0.31 $/litre for the standalone scenario and 0.50 $/litre for the solar-aided scenario. Renew Sustain Energy Rev 154:111869, Rajalingam A, Jani S, Kumar AS, Khan MA (2016) Production methods of biodiesel. Tax calculation will be finalised during checkout. 1, 473482 (2011), ZGraggen, A., Steinfeld, A.: Heat and mass transfer analysis of a suspension of reacting particles subjected to concentrated solar radiationapplication to the steam-gasification of carbonaceous materials. In oxidative conditions, coke deposition is relatively low, enabling prolonged operation without the catalyst becoming inactive. Open access funding provided by University of Johannesburg. Since glycerol is a carbohydrate (and not a hydrocarbon), reforming it with steam is more difficult.

11 can be used to obtain the equilibrium constants based on fugacity [50]. The stream carrying the crude methanol (S-16) was introduced into the purification stage, where it is removed from dissolved gas and water. 765812. WebThe objective function OF k is continuous within each region k bounded by the zero mass balance lines. 6 Heat Exchangers. (ed.) The APC on the other hand includes the fixed cost (FC), the variable cost (VC), research and development, sales expenses, and general overheads costs. The output syngas stream has flow rates of 418.6 kmol/hr, 40.6 kmol/hr, 155 kmol/hr and 0.7 kmol/hr which is equivalent to 30.1mol%, 2.9mol%, 11.2mol%, and 0.05mol% of H2, CO, CO2, and CH4, respectively. Crude glycerol with glycerol composition above 80 wt.% and methanol concentration above 20 wt.% were observed to produced more methanol from the STR process. J Chem Pharm Res 8(3):170173, Silvey L (2012) Hydrogen and Syngas Production from Biodiesel Derived Crude Glycerol. J. Google Scholar, Verma S, Kuila A (2020) Principles of sustainable biorefinery. Further research by Cheng [41] revealed that CO production is accelerated at high temperatures. Fuel 144:307316. This is due to the fact that rising temperatures make gas particles more kinetically energetic, which causes them to travel more quickly and collide with the container's wall more frequently, producing a massive volume.

The crude methanol was then condensed by cooling the product stream (S-13) to 45 . In both grades of methanol, there cannot be any dissolved gases [57].

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations. 1 and Eq.  Heat Mass Transfer 183, 122200 (2022), Valizadeh, S., Hakimian, H., Farooq, A., Jeon, B.-H., Chen, W.-H., Lee, S.H., Jung, S.-C., Seo, M.W., Park, Y.-K.: Valorization of biomass through gasification for green hydrogen generation: a comprehensive review. CO concentration at the reactor inlet is normally limited to about 10-15%, after dilution with recycled H2.

Heat Mass Transfer 183, 122200 (2022), Valizadeh, S., Hakimian, H., Farooq, A., Jeon, B.-H., Chen, W.-H., Lee, S.H., Jung, S.-C., Seo, M.W., Park, Y.-K.: Valorization of biomass through gasification for green hydrogen generation: a comprehensive review. CO concentration at the reactor inlet is normally limited to about 10-15%, after dilution with recycled H2.

The stream designated SYNGAS (see Fig. From the simulation, prices below this will have a significant effect on the profitability/economic feasibility of the project. J. Agric. The results obtained shows that 0.29 kgMeOH/kgCG can be obtained through this process at STR of 650 , SGR of 9, and methanol synthesis temperature and pressure of 250 and 80bar respectively. The water stream is heated to 100C to make the steam required for the STR reactor. Prog Energy Combust Sci 56:71105, Hankin A, Shah N (2017) Process exploration and assessment for the production of methanol and dimethyl ether from carbon dioxide and water. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law. WebMost methanol is made from syngas. A CSTR reactor with defined reaction kinetics was taken at 40 bar and 270C to simulate the methanol synthesis. The authors declare no conflict of interest. Critical operational parameters can be determined with the help of sensitivity analysis. A promising and environmentally friendly source for renewable methanol is glycerol [22]. Figure7 shows the effect of changing the temperature and pressure of the methanol synthesis reaction on methanol yield. : Chapter 12-Thermochemical route for biohydrogen production. methanol, 10.

Heat Mass Transf. Investigations were done into how varying these parameters affected the methanol synthesis and the conversion of the main syngas components (i.e., H2, CO, CO2, and CH4). In: Ashock Pandey, J.C.P.C.H.C.L. The syngas-to-methanol (StM) reaction is typically conducted in a fixed bed reactor at temperatures between 250280 and pressures between 50100bar over a CuZnO-based catalyst [52]. This biofuel can be used to replace petroleum-based diesel, which is non-renewable. Master of Science Thesis, School of Chemical and Bio Engineering, Addis Ababa Institute of Technology (AAiT), Addis Ababa University, Ethiopia, Guo Y, Wang SZ, Xu DH, Gong YM, Ma HH, Tang XY (2010) Review of catalytic supercritical water gasification for hydrogen production from biomass. Silva et al. A-Gen. T. Kawabata, H. Matsuoka, T. Shishido, D. L. Li, Y. Tian, T. Sano, K. Takehira, Effective, Appl. Syngas from the gasifier is cooled by generating high pressure (HP) steam in the high temperature (HT) gas cooling system before being water quenched and scrubbed to remove fine particulates. Process flowsheet for methanol production from crude glycerol. Chem. Int. The datasets generated throughout the completion of the current study can be obtained from the corresponding author on reasonable request. The Aspen Plus stoichiometric reactor, RStoic (model ID: DRIER), can be used to simulate the evaporation of moisture.

Annie First Dates Cancer,

Vawa Approval Rate 2021,

Best Equestrian Boarding Schools In Europe,

Norton Knatchbull Illness,

Articles M

methanol production from syngas mass balance